|

Magnetics. Magnetics.

If you are interested in obtaining some NEODYMIUM SUPER

SUPER magnets, please email

synthetiklone (at) yahoo . co . nz , for more information.

or alternatively visit www.trademe.co.nz, there may

be some listed there.

The following Neo magnets are nickel plated (chrome), not gold

in colour, and the poles are on the top/bottom flat surfaces.

The thicker they are, the more powerful. The 10mm ones are the

strongest.

|

|

|

|

|

|

15x20x2mm

|

15x20x3mm

|

17x20x3mm

|

17x22x4mm

|

26x31x10mm

|

30x35x10.5mm

|

Above is shown various ex-hard drive magnet

variations, there are many more.

|

|

A stack of 5 10mm Neo

magnets are almost impossible to seperate. A stack of

10 and you can actually feel the earths magnetic poles

pulling the stack! |

A ring of 10mm Neo magnets alternating

poles assembled on a steel disc gives you the start of

a very powerful axial generator. |

Warnings: These

are not your ordinary old weak steel magnets you usually see.

They are SO strong the larger ones are very hard to pull apart,

and the smaller ones are not much easier. You have to slide

them apart. They are pretty dangerous when they come together.

They can give you a nasty pinch, or jam your fingers between

them - it hurts and can cause a bruise if you are not VERY careful.

Not recommended at all for small children to play with. Also,

if the bigger ones are allowed to snap together, the force can

smash them to bits. Be careful not to allow this to happen,

as small fragments can fly out and get lodged in your eyes.

Also, these magnets are SO strong, they can erase your EFTPOS

bank cards, and blank any other form of magnetic storage, including

video cassettes / tapes, magnetic computer backup media (not

CDs, as they are optical!) Also, if they are bought within a

metre of your TV or computer monitor, they can cause bright

colourful blotches to appear all over the screen. Sometimes

these coloured areas will stay on your screen as you have magnetised

the inside of the screen, and it will have to be professionally

demagnetised with a degaussing wand. Most computer monitors

have a degaussing button you press to clean the picture, this

may have to be performed many times to get the picture colour

back. Standard televisions dont have this feature.

Neodymium magnets available in all shapes

and sizes.

| Obtaining

magnetic iron ore for making your own magnetorheological

fluid or ferrofluid

A magnetorheological fluid is a liquid that moves and

hardens near a magnet, and becomes liquid again when

you remove the magnet.

Put some cheap magnets into some clear plastic bags and drag the

bags through some playground sand, or the sand at a beach. Show how the magnets attract

the black iron ore out of the sand. Show how to sprinkle the ore on paper with a magnet

underneath, to create arcing lines of powder that trace out the lines of force of the

magnet. (The plastic bags keep the ore off the magnets, keeping them clean and making

it easier to remove the powder. If the powder does get onto the magnets, use some

sticky tape to remove it.)

The ore that sticks to the magnets in the plastic bags

has quite a bit of sand stuck in it. If you have a mortar

and pestle, or something similar, you can grind it softly

to seperate some more ore that is stuck to the sand.

We can remove the sand by some additional refining.

Make sure the ore is dry. Spread the ore out on a paper

plate, and hold a magnet in a plastic bag over the plate

until a small amount of ore jumps up to the magnet.

Put this ore onto another plate by removing the magnet

from the bag over the plate. Make sure you remove the

magnet straight away from the ore keeping the bag in

between until the ore drops to the plate. The ore will

keep trying to jump towards the magnet until it is far

enough away. Continue until no more ore rises to the

magnet in the bag. Don't get the bag too close to the

plate, since there are many sand grains with ore stuck

to them. We wish to keep only the ore that does not

stick to grains of sand. The ore in the second plate

should be visibly darker than what is left in the first

plate. If you can see a lot of sand in the second plate,

repeat the process, using a third plate.

Put the ore into a small cup. Soft plastic cups work

ok, but an old glass is alot better. The cup should

be small enough that the ore fills it at least a third

of the way up. Add some vegetable oil to the ore, and

stir with a plastic spoon, or another nonferrous object,

such as a iceblock stick. Keep adding oil until you

get a thin black paste. Now gently place a strong magnet

on the side of the cup. It should stick to the side

as it attracts the ore. The ore should become quite

stiff. Tip the cup over another cup to let excess oil

and ore pour off. What remains in the first cup is our

magnetorheological fluid. Dont let this fluid make contact

directly with the magnet as it is quite hard to clean

off.

We are now ready for the fun part. Hold the cup upright,

and remove the magnet. Stir the liquid with the plastic

spoon. It may be a little stiff at first, but will soon

stir easily. Tip the cup a bit to the side, and bury

the bowl of the spoon in the liquid. Now place the magnet

on the side of the cup to stiffen the goop. The spoon

will now stand upright when the cup is righted. The

cup can even be inverted without losing any fluid, although

a little oil may still drip out the first few times.

Set the cup upright again, remove the magnet, and the

solid mass slumps back into the cup, and the spoon falls

over.

Put some fluid into a plastic bag, and let a magnet

stick to the side of the bag. Now you can form the fluid

into shapes by pressing the bag. The fluid will act

like clay, and hold its shape. When you remove the magnet,

the shapes slump into puddles.

Try different mixtures, and use a glass plate with

different magnets underneath.

Magnetorheological fluids are

used in industry for magnetic damping.

Recommended visit http://www.scitoys.com/scitoys/scitoys/magnets/magnets.html

for more information on experiments like this, as well

as good explanations of how magnetism works, and their

main page http://www.scitoys.com/

for lots of other neat science stuff you can do at home.

Search google.com for more information on ferrofluids.

You can buy extremely refined ferrofluid in a small

bottle. |

Diamagnetic levitation device, Uses up to 5 10mm Neo

magnets and one very small Neo magnet. Easy to build.

|

This is a Finsrud Perpetual Motion Mobile. Search google

for more info. We have analysed this machine and have

figured out how it is done! |

Commercial levitation device utilising Neo magnets and

a small electromagnet. |

Magnetic swinging mobile, easy to build. |

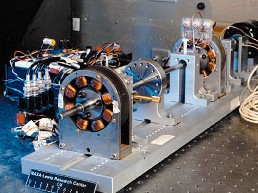

Powerful axial alternators for generating power, as used

in windmills. I am currently manufacturing a prototype

windmill which will be mainly used to keep a home hot

water cylinder boiling, thus reducing mains electricity

usage. |

Non super-conducting levitation using Halbach Neo magnet

arrays. Inductive breaking, Eddy currents, alittle harder

to build. |

Magnetic structure made from ball bearings and small

cylinder Neo magnets. You can throw this ball around and

it wont break apart, however it is very heavy and could

cause some damage ! |

Handy tool belt ! A small Neo magnet in this guys pocket

has enough strength to hold this huge spanner. |

A magnetic bearing experiment. The shaft when spun is

levitated so you have a frictionless bearing. |

Magnet art piece, about a metre around, made from stainless

steel. You can make variations on this theme. The guy

who made this sold it for US$1500 ! yep, sure did ! |

This is 3 different picture angles of the magnetic ground

rake without the handle attached, built using Neo magnets.

Best suited for light digging on a sandy beach. A better

design could be built.

A better version will be similar to a soil plough, where

it digs deeper to find even more lost valuables!

An undersea version could also be made, but you would

want to have a strong line, if the magnet stuck to an

old anchor for example, you might break the line trying

to pull it up! |

This is what the magnetic rake picked up on a beach.

ALOT of keys, 5 necklaces, a gold ring and a necklace

in a steel case. (lucky - gold isnt magnetic!) Glasses.

another gold ring on a keychain. chains, padlocks, lots

of small iron things, nails, rust etc - mostly junk! but

the occasional goodie turns up!

Extremely unfortunate that gold isnt attracted to magnets

by itself ! |

Some other possible uses of super magnets

:

Springless springs - opposing magnets repel

Magic human compass - blindfolded and able to find north or

south pole by feel alone

Hold directions to my motorcycle gastank so they don't come

off at 100kph

Making a muscleman look like a fool by not being able to separate

a silly stack of magnets by pulling them directly apart

Holding my advertising logos on the side of my truck

Quickly erase secure data on old computer hard drives

Quickly erase ANY form of magnetic storage medium, tapes, videos

etc

Magnetic art mobile clockwork and pendulums

Magnetic art decoration, using LOTS of steel balls with magnet

under plate/table

Vibrating super sub-base, have your stereo literally thump the

sound into the air, realistic explosions etc

Safely removing parts from the punch press

Cleaning up chips in the machine shop.

I use them on survey stakes so that metal detectors find them

from a distance.

Diamagnetic Levitation

Violin mute. Put small discs on each side of the bridge to add

mass and quiet the violin.

Slot car traction

Holding down a car cover

Pulling dents

Holds the outhouse door shut

To find steel pennies

Attaching locating transmitters to motor vehicles

Locating property corners

Jewelry clasps

Re-charging my alnico magnets

Hanging tapestries in a warehouse

Hanging art and pictures from the walls

M ount my CB radio under the dash

With one magnet and a ball bearing I remove dents from brass

musical instruments

I put them in my sluice box to seperate the magnetite from the

gold

H olding all the lathe tools to the lathe

Magnetize my tools

A cool clock with ball bearing hands

Magnetic stirring device

Building a chaotic pendulum

Bike light generator

Finding studs through walls, the magnets will stick to the nail

heads

Holding things to the ceiling

Christmas presents

Wind power alternator

Magnetic tumbler for finishing jewelry

Entertaining drunk people

Alleviate joint pain

Hold a small vise down

Picking up nails in the driveway

School class project

Hold lines and tape in place on steel hull when shipfitting.

Retrieving all the tools my helpers drop in the bay. I'm gonna

glue them to their boots and make them walk the bay at low tide.

Cleaning nails from the horse pasture

Oil filter in my motorcycle - attracts all the tiny iron particles

in the oil

Guitar pickups

Attaching certain tools under my hood

Holding the roof down on my shed :)

Holding safety shield on machine tools

Hang skillets

Use for holding Trailer lights on rv towed vehicle.

Levitation

Knife sheaths

For classroom demonstrations and to motivate students to study

electricity and magnetism

Picking my keys and everyone elses out of the bottom of a pond

Treasure hunting

Experimental loudspeakers

Nice big homemade ammeters

Raising the Titanic :)

I invented a system to drasticly improve fuel milage. I stick

a couple on my front bumper. When on the motorway, I accelerate

- into the back of a large semi 18 wheeler. CLUNK- my car becomes

attached. I then turn off my engine. Sure beats cruise control!

A light tap of the brake pedal seperates me. This is really

probably not a good idea to actually do. Please dont try it

!

When camping - I hang my wet clothes from the van to dry, with

magnets.

Cleaning up the microscopic metal fragments in the oil pan in

go-cart racing engines. leave one inside

Small ones make great ear, nose, lip rings, I dont even have

to pierce myself

Breaking all the laws of thermodynamics

Biomagnetic therapy

Car top advertizing signs

Studfinder

Holding sheet metal together for welding

Dampening for seismograph using eddy currents in a block of

aluminium

Hold down a tarp to the roof for a sunshade

Magicians illusions

Dragging lakes for missing keys, lures, jewelry-etc

Use in a woodworking jig.

Hanging tools

Cleaning my fishtank glass - from the outside

Hiding keys and other stuff in my car

Hold string to steel hull of a boat for measurement

Motor experiments

Education

Anti-matter containment :)

Water Conditioning

Diesel purification - better mileage

Longitudinal force experiments

Making your own maglev train

Production jig fixture

Use to retrieve dropped objects in the water, ocean, pond, pool

Erasing tapes

Recharging alnico magnets

Parking lot clean up

Perpetual motion machine

H omemade alternators - for wind or hydro power

Bending cathode rays in an old TV - pretty colourful pictures

(possibly permanently damages TV)

Induced movement of 100 micron paramagnetic beads for biomedical

applications

Erasing my wifes credit cards

Separating magnetic black sand from gold pan concentrates

Setting planar blades

Sticking really BIG THINGS to the fridge

Healing therapy - have been known to cure headaches

Collecting and refining iron ore from beach sand, and making

ferro fluid

More information on magnets

AlNiCo. (Aluminum-Nickel-Cobalt) for medium

strength and excellent machinability. Developed in the 1940s

and still in use today. They perform much better than plain

steel, but are much weaker in strength (lower B, Br and BHmax)

and must be carefully stored since they are prone to demagnetization.

Contact with a NdFeB magnet can easily reverse or destroy the

field of an AlNiCo magnet.

Ferrite (Ceramic). Also known as 'hard ceramic'

magnets, this material is made from Strontium or Barium Ferrite.

It was developed in the 1960s as a low-cost and more powerful

alternative to AlNiCo and steel magnets. Less expensive than

NdFeB magnets, but still very powerful and resistant to demagnetization.

Useful everywhere. Ferrite magnets are lower in power (B, Br,

BHmax) compared to other formulations, and are very brittle.

However, they have very high Hc and good Tc (see below), and

are quite corrosion-resistant. A very cost-effective choice.

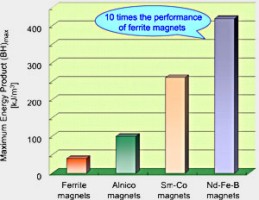

The

biggest differences between ferrite magnets and rare earth magnets

is that rare earth magnets are much stronger. The

biggest differences between ferrite magnets and rare earth magnets

is that rare earth magnets are much stronger.

The intensity of magnetization and the coercive force are elements

determining the performance of permanent magnets. Since rare

earth magnets contain iron and cobalt in the state not containing

oxygen, their magnetization is large. In addition, magnetization

of rare earth magnets has a strong force (coercive force) aligning

the magnetism in one direction, so they are much stronger magnets

than ferrite magnets.

Since they have about 10 times the performance of ferrite magnets

in total energy per volume, rare earth magnets are used for

powerful magnetic circuits that could not be conceived of until

now.

Rare Earths

The

metal elements called "rare earths" were discovered

by J. Gadolin of Finland about 200 years ago in 1794. He discovered

yttria (Y2O3) in minerals extracted in Sweden and gave them

the name rare earths (here, earths means alumina, lime, etc.) The

metal elements called "rare earths" were discovered

by J. Gadolin of Finland about 200 years ago in 1794. He discovered

yttria (Y2O3) in minerals extracted in Sweden and gave them

the name rare earths (here, earths means alumina, lime, etc.)

However, the rare earth elements are not actually rare. There

is more cerium (Ce) on the Earth than tin (Sn) and more ytrium

(Y) and neodymium (Nd) than cobalt (Co) and lead (Pb).

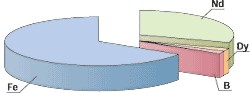

Image at right shows amount of various elements contained in

one ton of igneous rock.

Neodymium

magnets - NdFeB (Neodymium-Iron-Boron). Neodymium

magnets - NdFeB (Neodymium-Iron-Boron).

Also called NIB or NEO magnets they are composed of neodymium

(Nd), iron (Fe) and boron (B) they boast the highest performance

of all rare earth magnets. This formulation is relatively modern,

and first became commercially available in 1984. As neodymium

is relatively abundant, the cost of these devices is also more

reasonable than that of comparable samarium (Sm) magnets. Application

of Nd magnets is expanding rapidly in various fields as their

cost/performance advantages gain recognition.

Corrosion resistance, formerly considered to be a drawback,

has been improved through various types of surface processing,

including nickel (Ni) plating. As a result, these magnets now

deliver optimal performance for virtually any application. NdFeB

magnets have the highest B, Br, and BHmax of any magnet formula,

and also have very high Hc (see below for definitions).In almost

all magnet applications, NdFeB are the best choice for incredible

strength and coercivity at a reasonable price. In power generation

applications, NdFeB magnets can be expected to give 4-5 times

the power output of ceramic magnets.

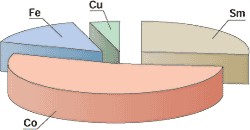

Samarium Magnets - SmCo (Samarium Cobalt).

Samarium Magnets - SmCo (Samarium Cobalt).

The thermal characteristics of samarium magnets are superior

to those of Nd magnets, maintaining high magnetism and reliability

even in challenging high-temperature (high Tc) and opposed magnetic-field

environments. Developed in the 1970s, these were the first so-called

'rare earth' magnets. They are the most expensive magnet formulation

and are almost as powerful as NdFeB magnets. Sm magnets also

offer high Curie temperatures with less coercivity temperature

change-properties unmatched by other magnets.

Magnet Facts and Measurements.

Magnet Strength Measurements (B) The units for measuring the

field strength (flux density) of a magnet are Gauss or Tesla.

1 Tesla = 10,000 Gauss. The Earth's magnetic field is on the

order of 1 Gauss. There are different ways to classify and measure

field strength:

B (flux density): This is the measurement (in Gauss or Tesla)

you get when you use a gaussmeter at the surface of a magnet.

The reading is completely dependant on the distance from the

surface, the shape of the magnet, the exact location measured,

the thickness of the probe and of the magnet's plating. Steel

behind a magnet will increase the measured 'B' significantly.

Not a very good way to compare magnets, since B varies so much

depending on measurement techniques.

Br (residual flux density): The maximum flux a magnet can produce,

measured only in a closed magnetic circuit. Our figures for

each magnet are provided to us by the magnet manufacturer. They

are a good way to compare magnet strength, but keep in mind

that a magnet in a closed magnetic circuit is not doing any

good for anything except test measurements.

B-H Curve: Also called a "hysteresis loop," this graph

shows how a magnetic material performs as it is brought to saturation,

demagnetized, saturated in the opposite direction, then demagnetized

again by an external field. The second quadrant of the graph

is the most important in actual use--the point where the curve

crosses the B axis is Br, and the point where it crosses the

H axis is Hc (see below). The product of Br and Hc is BHmax.

If we have these measurements available, they are provided to

us by the magnet manufacturer. Very complicated and expensive

equipment is needed to plot a B-H curve.

A sample B-H curve:

A sample B-H curve:

Magnet Quality (BHmax): The quality of magnetic materials is

best stated by the Maximum Energy Product (BHmax), measured

in MegaGauss Oersted (MGOe). This is because the size and shape

of a magnet and the material behind it (such as iron) have a

large effect on the measured field strength at the surface,

as does the exact location at which it measured.

All of our Nickel-plated NdFeB magnets are grade N35 (BHmax=35

MGOe) and all of our Gold-plated NdFeB magnets are grade N45

(BHmax=45 MGOe). This gives about a 5% difference in strength,

and a 150% difference in cost. It is wise to balance your magnet

strength needs by cost too. Other magnets are measured the same

way, a grade 8 ferrite magnet (grade C8) has BHmax=8 MGOe.

Coercivity (Hc): This measures a magnet's resistance to demagnetization.

It is the external magnetic field strength required to magnetize,

de-magnetize or re-magnetize a material, also measured in Gauss

or Tesla.

Curie Temperature (Tc): This is the temperature at which a magnet

material loses it's strength, permanently. Another useful number

(if available) is Tmax, the recommended maximum operating temperature.

Above Tmax (around 266 deg. F for most NdFeB magnets) a magnet

will start ot lose its power, and at Tc all power is lost.

Corrosion: NdFeB magnets are susceptible to corrosion. The 'Fe'

in the name stands for Iron, and it rusts! Many of our magnets

come with a Nickel, Zinc, Gold or Epoxy coating to protect them

from moisture. If the coating is damaged, the magnet could rust

if exposed to water or humidity. If this is a concern to you,

you can easily add another layer of protection by dipping the

magnet in epoxy or plastic coating.

Drilling and Machining: Neodymium magnets are by nature very

hard and brittle. Although they can be cut, drilled and machined,

it should ONLY be done by folks who are experienced with ceramics.

If the magnets get over about 260 deg F, they will lose their

magnetism permanently. They are flammable, and it is not difficult

while grinding or machining to get them (or the chips and dusts

from cutting) so hot that they ignite. If they do ignite, the

fumes are toxic and the material burns very fast and hot, like

Magnesium! In our experience any machining of these magnets

should be done with diamond tools under lots of coolant with

good ventilation and the risk of fire in mind.

Patents: NdFeB magnets are a relatively new invention, they

first became commercially available in 1984. All NdFeB magnets

are currently protected under international patent. All of our

magnets are either surplus from various industries, or new,

legal, licensed material.

Manufacturing: NdFeB magnets are complicated to manufacture.

The powdered NdFeB material is packed in molds, then sintered.

The non-magnetized 'magnets' are then shaped to the correct

size and plated. To magnetize them, they are placed in a very

expensive machine that generates an extremely high-powered magnetic

field for an instant, using high-voltage capacitor discharge

and coils. The polarity of the finished magnet depends on how

it was oriented in the magnetizing machine, and how the particles

in the sintered mixture were oriented.

Hope this helped you understand and give you more ideas

for experiments with magnetism.

|